How to Do Fluorescent Mag Particle Inspections [Video]

Learn about the magnetic particle inspection method of nondestructive testing, including basic steps for NDT with fluorescent magnetic particles using a magnetic wet bench..

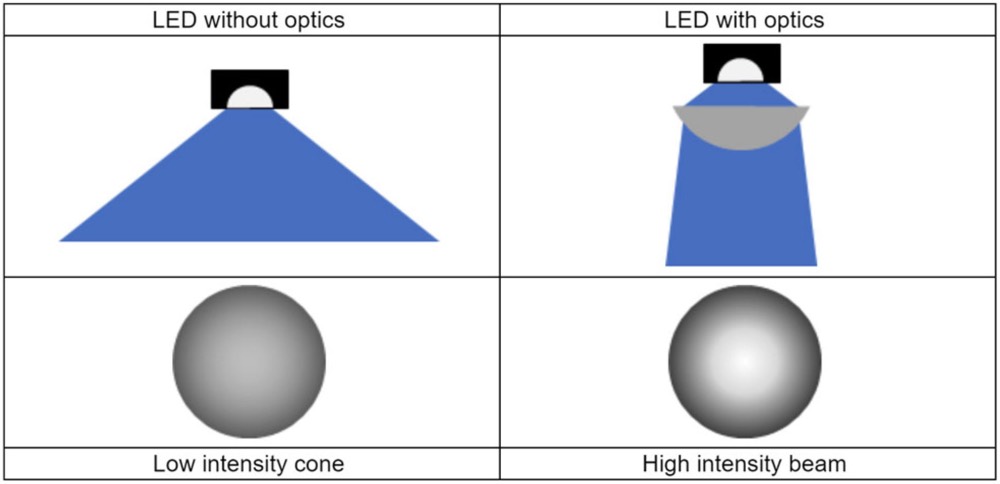

An LED by itself, without optics, emits light in all directions. That may sound like a favorable property because it means an LED will light up a wide beam. However, the problem for NDT inspection with this type of LED is that you don’t get much intensity at any one spot. That’s acceptable for background illumination, but for inspection purposes you need to meet minimum intensity limits set by standards committees.

Enter LED Optics – Optics focus the LED light into a usable more concentrated beam. For a UV LED lamp to be useful for NDT for inspection, there needs be an optic over the LED source to provide a useful intensity. See the below figure comparing how light behaves both with and without optics.

1. Optics must be selected to balance intensity against beam profile

2. Common LED optics are made from PMMA

3.Optics originally developed for UV LEDs are treated to transmit UV-A down to 320 nm

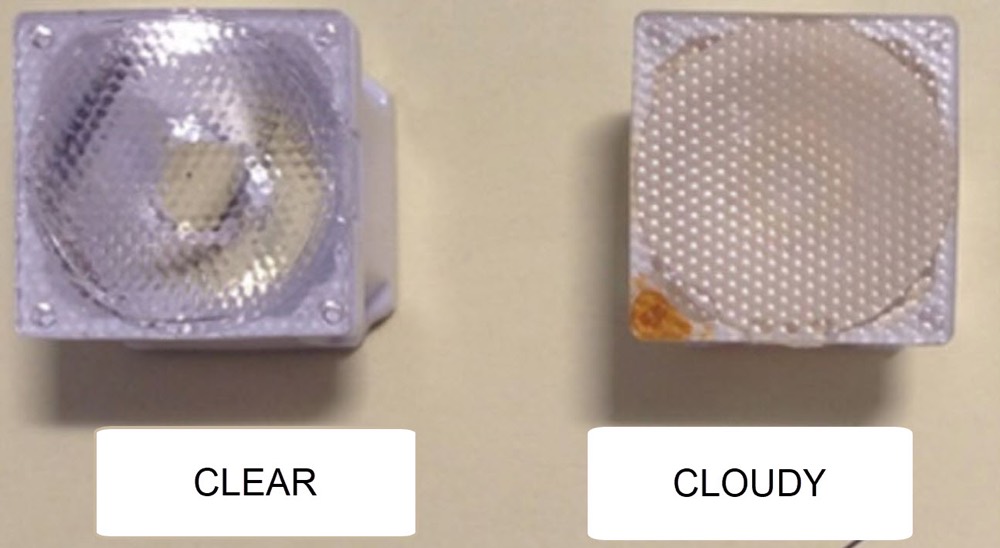

Lamp manufacturers need to balance all these factors into the design of an inspection lamp that (A) has a useful intensity, (B) has a beam with a smooth and even profile without hot spots, and (C) is long-lasting and durable.

With the EV6000, Magnaflux developed custom LED optics made from UV-stable material. That means the lenses will not solarize and the UV-A intensity will not degrade over time. All LED UV-A Lamps from Magnaflux use these custom optics for dependable performance and a long life.

Still have questions about LED optics? Want more information about our Magnaflux products such as the standard intensity LED lamp (EV6000) or high intensity EV6500? Feel free to reach out to us at [email protected] or 800-221-1116

Source:

Geis, David. "3 Facts About LED Optics and The Impact of Ultraviolet Light". Magnaflux Blog, 5 March 2019, https://www.magnaflux.com/Magnaflux/Resources/Blog/3-LED-Optic-Facts

Learn about the magnetic particle inspection method of nondestructive testing, including basic steps for NDT with fluorescent magnetic particles using a magnetic wet bench..

User-check requirements for LED UV-A lamps, and how to plot the beam of an LED UV-A lamp for Airbus AITM6-1001 Issue 11..

Learn about the penetrant inspection method of nondestructive testing, including basic steps for NDT with an AMS 2644 Type 1 water washable penetrant..